Industrial electrical systems are essential for the smooth operation of manufacturing plants and other industrial buildings. However, troubleshooting industrial electrical systems can be challenging, especially for those without a background in electrical engineering. In this helpful guide, we will answer some of the frequently asked questions about troubleshooting industrial electrical systems, aiming to provide you with the necessary knowledge to safely and effectively address any issues that may arise.

Troubleshooting Industrial Electrical Systems Tips.

What are common electrical issues in industrial buildings?

Industrial buildings often experience various electrical issues, including power outages, electrical equipment malfunctions, circuit overloads, and faulty wiring. These problems can result in production downtime, safety hazards, or even damage to equipment.

How can I ensure my safety when troubleshooting an industrial electrical system?

Safety should be your top priority when working with industrial electrical systems. To ensure your safety, always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and non-conductive footwear. Moreover, always de-energize the system before starting any work and use lockout/tagout procedures.

What are some basic troubleshooting steps I can follow?

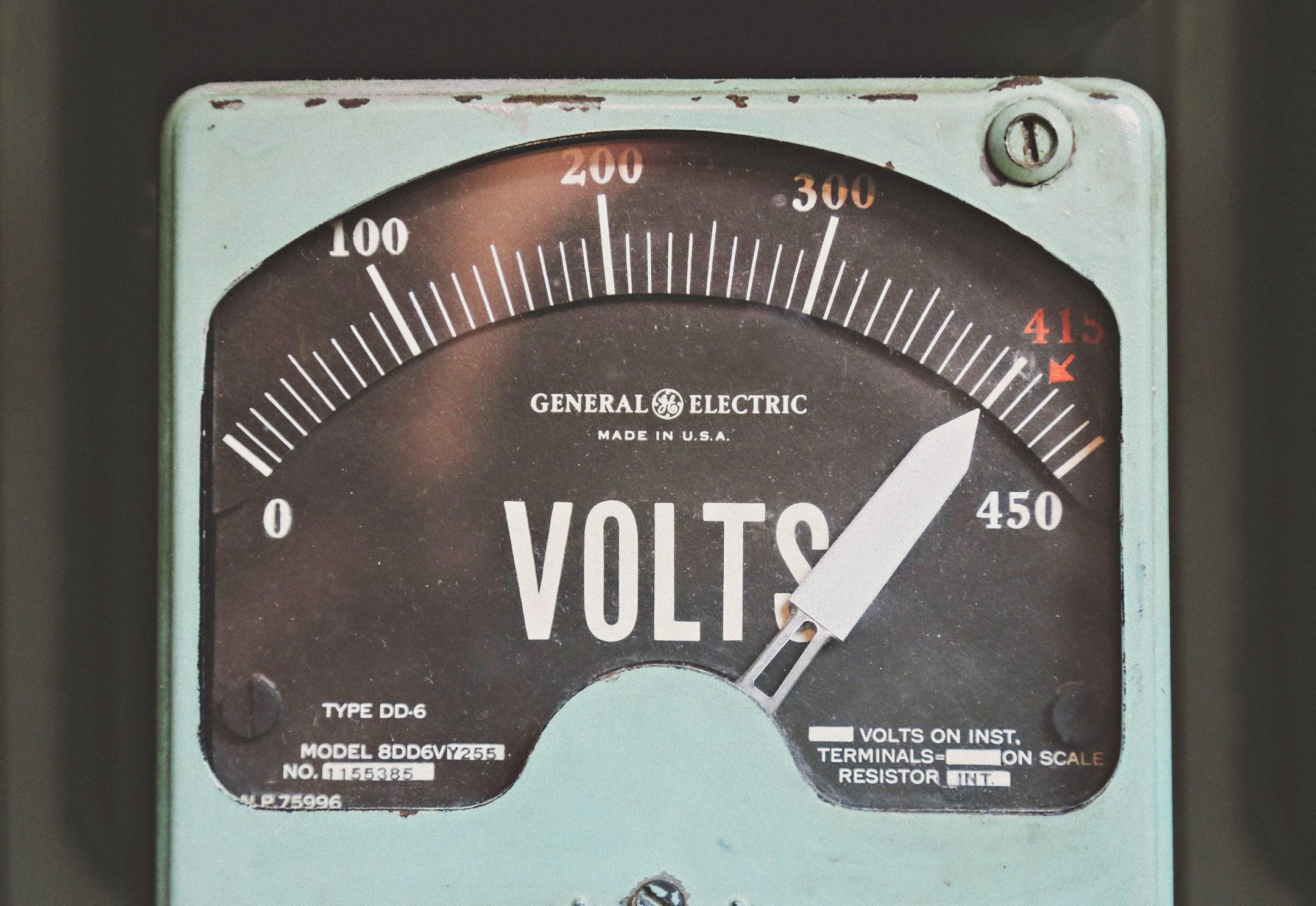

When troubleshooting an industrial electrical system, it is important to follow a systematic approach. Start by gathering information about the problem, such as the specific symptoms, when it occurs, and any recent changes or maintenance performed. Then, visually inspect the system, looking for physical damage or loose connections. Next, use appropriate testing equipment to measure voltages, currents, and resistances. Finally, analyze the collected data to identify the root cause of the problem.

How can I identify the source of an electrical problem?

To identify the source of an electrical problem, you can use various methods. Start by checking for obvious issues like tripped circuit breakers or blown fuses. Then, use a multimeter to measure voltages at different points in the system. If the voltage is significantly lower at a specific point, it may indicate a faulty component or connection. Additionally, thermal imaging cameras can help identify hotspots that could indicate overloaded circuits or faulty equipment.

What are some common reasons for circuit overloads?

Circuit overloads occur when the electrical load on a circuit exceeds its designed capacity. Some common causes of circuit overloads in industrial settings include running too many devices simultaneously on the same circuit, using equipment with higher power requirements than the circuit can handle, or adding new equipment without considering the existing load.

How can I prevent electrical issues in the future?

Regular maintenance and inspections play a crucial role in preventing electrical issues. Develop a maintenance schedule that includes cleaning, tightening connections, and testing equipment. Additionally, train your staff on electrical safety guidelines, including proper usage of equipment and reporting any anomalies. Consider implementing a predictive maintenance program that utilizes advanced techniques like infrared thermography or vibration analysis to detect potential issues before they cause problems.

Do I need to shut down the system when troubleshooting industrial electrical problems?

In most cases, it is recommended to shut down the system before troubleshooting. This minimizes the risk of electrical shock and protects you from potential harm. However, in some situations, such as when testing specific components, it may be necessary to have the system energized. In such cases, extreme caution must be exercised and all necessary safety measures followed.

Is Your Industrial Electrical System Having Issues?

Trust the experts at Cogburn Electric Inc. to troubleshoot and fix any issues your system may be experiencing. Voted the best of Marion 2024 for electricians, we have a passion for helping people. Our core focus is to provide the best electrical services we can to our clients, and we’re confident we have the experience needed to help you get your system back up and running. You can learn more about our industrial services online, or contact us to schedule a consultation today.